Hyperion tests

every optical specification on the print 100% and provides complete inspection

data and Certificate of Compliance (COC) for each production batch. Our

manufacturing and QA inspection processes strictly follow ISO:9001:2015

standards, offering our customers a worry-free procurement experience.

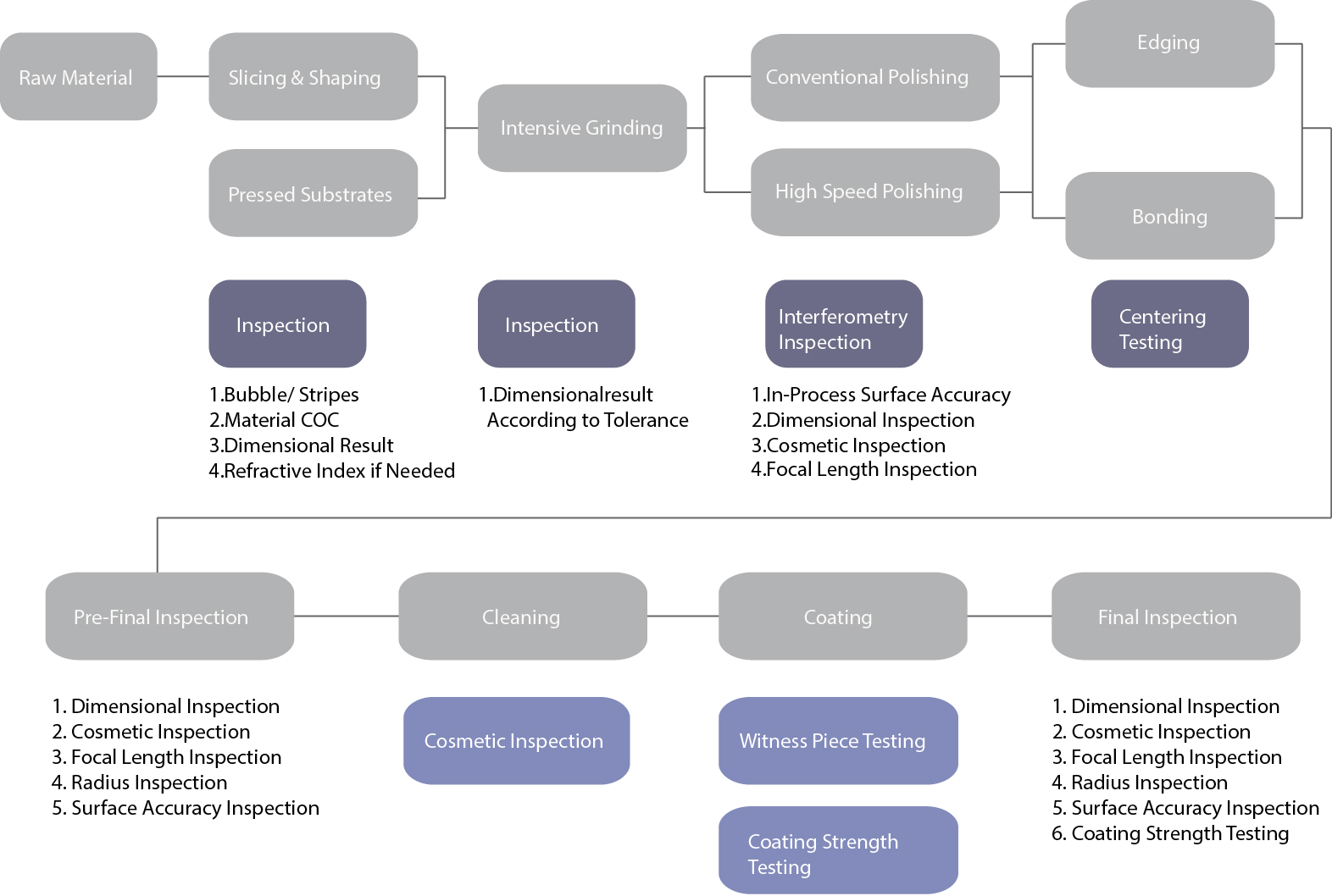

The flow

chart below illustrates

the

standard QA processes in a spherical lens production at our facility. An assigned

QA manager oversees the production process and implement corresponding

quantitative measurements at every step of production to ensure lens quality.

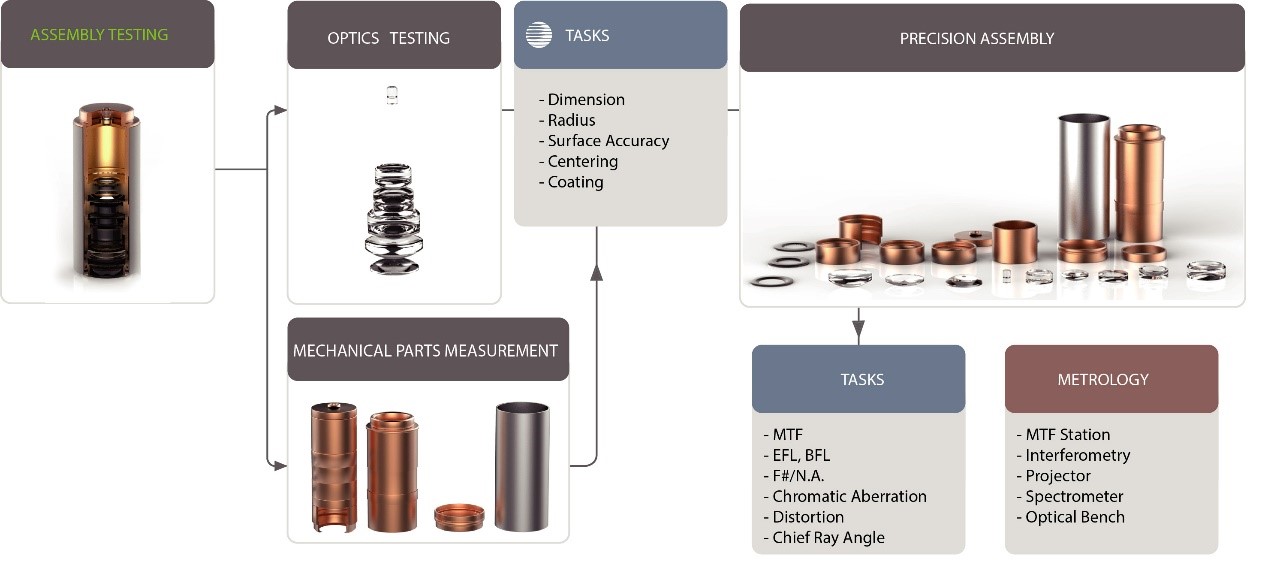

After the optics are completed,

they are now ready for assembly. Our skilled assembly technicians employ a full

range of metrology during assembly to finetune alignment precision and

accuracy.

Furthermore, Hyperion

conducts thorough testing to ensure that the assemblies we produce will meet or

exceed the optical performance specifications required for your application

needs. A detailed report on MTF plots, focal length, F#, chromatic aberration,

and distortion will be provided.

Below chart

illustrates Hyperion’s inspection process for precision assembly

Our documentation includes all critical

parameters; Hyperion’s packaging and labeling provides safe and accurate traceability

for each batch shipment. A detailed inspection report including dimensional

measurements, Zygo interferometry reports, and actual coating curves are

provided along product shipment.

Contact us today to request a sample inspection

report.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr