<img width="607" height="308" title="Optical Machining Centers " align="" alt="Optical Machining Centers " src="/uploads/image/20170310/15/asphere-lens.jpg" p="" <="">

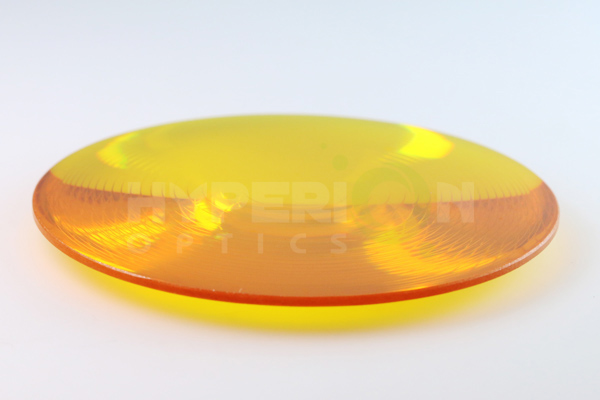

The complex surface profile of an asphere can significantly reduce or even eliminate spherical aberrations comparing to spherical lenses. Hence, asphericals have been increasingly more widely explored and adopted during the optical design stage.

Aspheres can replace a complex multi-element spherical system to achieve a lighter and more compact optical system. The resulting design has higher transmittance and in most cases, costs less than the multi-lens spherical design, especially at production volumes.

Hyperion Optics is equipped with the Optotech aspheric CNC machine that offers Contour Deterministic Micro Grinding (CDMG) service – the machine grinds the optical material to achieve ultra-high precision shape by leveraging the accuracy and repeatability of a computerized, numerically-controlled machine mechanism. Our process begins by grinding the bulk raw material into the closest fitting sphere, and then contouring the aspheric shape from edge to center. Typical available materials within our fabrication capabilities are optical glass, ZnSe, ZnS, BaF2, GaAs, and chalcogenide glass types. We also accept materials supplied by our clients

Optical Machining Centers capability:

Capacities from 5mm to 400mm

1,000 to 24,000 rpm tool spindle

Automatic curve correction

Tool & Workpiece probing system

Dual tool spindles option

Hyperion’s manufacturing procedure eliminates the need for additional investment on tooling and processing fixtures for spherical substrates and preparation, thereby giving customers a quick start to the production schedule. While the aspheric part is being grounded, the profilometer will conduct and transfer measured data to the polisher. In our polishing process, our experienced operators can control the aspheric form error within 1 micron (depending on the diameter of the parts).

MOQ starts at two pieces to ensure optical performance approval. Our fast asphere prototyping has become one of our most popular services for Low Ratio Initial Production (LRIP) projects. We can process both spherical and aspherical parts simultaneously for custom objective and/or eyepiece designs, thereby securing a reliable timeline management to meet the tight timing requirement. In addition, we offer competitive pricing for aspheric coating within our prototyping packages.

Our rapid aspheric prototyping / LRIP package is ideal for you if:

1. Off-the-shelf aspheric parts do not fit perfectly in your system, Hyperion Optics can design and manufacture the custom aspheric lenses based on your system-level optical requirements.

2. You need custom, built-to-print aspheric lenses. Hyperion Optics fabricates custom aspheric lens and provides complete inspection reports per your print requirements.

3. Reverse engineering is required on an existing lens where you need to replace. Hyperion Optics runs in-depth mapping and optical performance testing on all lens products prior to reverse engineering; then, we proceed to redesign and system optimization and finally, manufacturing and assembly.

Please contact one of our asphere experts today and find out how a custom aspheric lens can help enhance and optimize your current lens system.

Still finding aspheric lens manufacturer? Leave us a message now.

Manufacturing Limits for Aspheric Surfaces Based on Form Error Tolerance | ||

Form Error > 2μm Lower Resolution Profilometry (2-D)1 | ||

Attribute | Minimum | Maximum |

Diameter (mm) | 3 | 250 |

Local Radius (mm) | -8 (Concave) | ∞ |

Sag (mm) | 0 | 50 |

Departure (mm) | 0.01 | 20 |

Included Angle (°) | 0 | 120 |

Form Error 0.5 – 2μm Higher Resolution Profilometry (2-D)1 | ||

Attribute | Minimum | Maximum |

Diameter (mm)3 | 3 | 250 |

Local Radius (mm) | -12 (Concave) | ∞ |

Sag (mm) | 0 | 25 |

Departure (mm) | 0.01 | 20 |

Included Angle (°) | 0 | 150 |

Form Error < 0.5μm Interferometry with Stitching (3-D) | ||

Attribute | Minimum | Maximum |

Diameter (mm)3 | 3 | 250 |

Local Radius (mm) | -13 (Concave) | ∞ |

Sag (mm) | 0 | 25 |

Departure (mm) | 0.002 | 1 |

Included Angle (°) | 0 | 120+5 |

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr