In many machine-vision systems, such as those used in semiconductor inspection, precise repeatable measurements must be made consistently. To ensure this occurs, system developers must turn to more expensive optical systems based on telecentric lenses with which to image these parts.

Many of the reasons for choosing telecentric lenses emerge from the limitations of more conventional lens systems. For example, should an object move even slightly within the depth of field of a conventional lens system, there will be an associated magnification change. In the past, magnification changes due to object displacement were calibrated by means of an additional camera or a depth sensor tracking the distance between the lens and the object. The use of a telecentric lens can substantially reduce or even eliminate such magnification changes and therefore remove the need for any additional camera and preprocessing of the image data that may otherwise be required to correct for any magnification errors.

Perspective or parallax errors can also be eliminated by the use of telecentric lenses. In conventional optical systems, closer objects appear relatively larger than those further away because the magnification of an object changes with its distance from the lens. However, telecentric lenses optically correct for this parallax error so that objects remain the same perceived size independent of a specific distance from lens.

Telecentric lens can solve above problems effectively in a specific working distance. Telecentric lens has same magnification which isn't change with DoF after focalization. Telecentric lens can provide superior image quality with low distortion and no parallax, so it can be used in high precise measurement and the detection of the work piece’s defect.

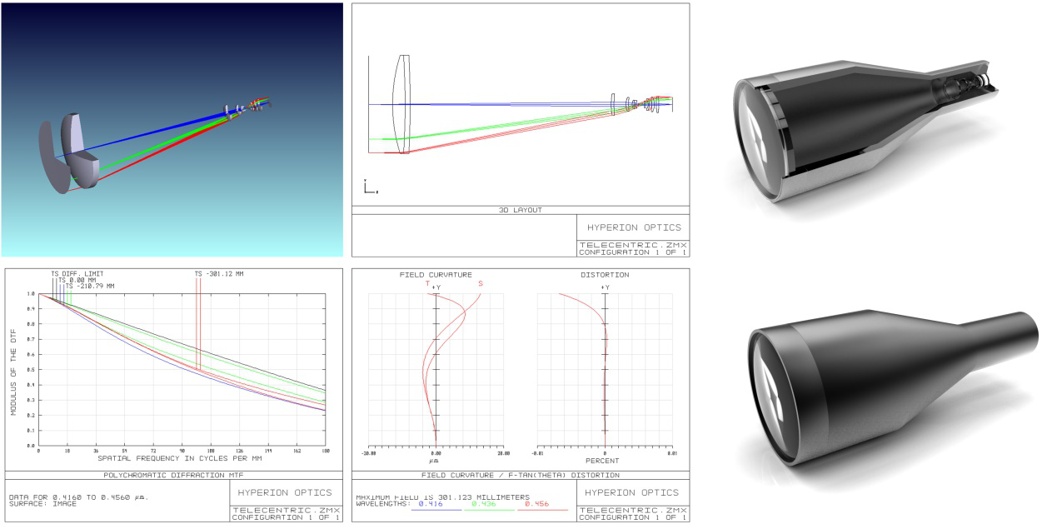

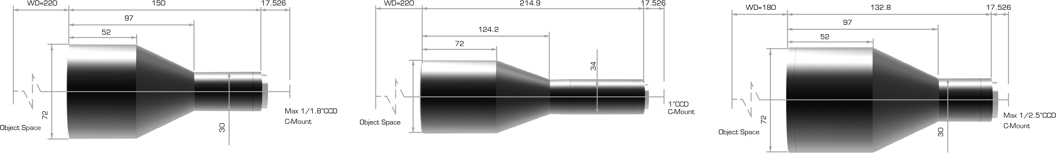

Off-The-Shelf Products

| Maganification | 0.3 | 0.3 | 0.3 | 0.3 | 0.14 | 0.22 | 0.22 | 0.5 | 0.55 | 0.345 | 0.367 |

| Working Distance | 180+/-2 | 180+/-2 | 180+/-2 | 220+/-2 | 180+/-2 | 200+/-2 | 200+/-2 | 220+/-2 | 220+/-2 | 220+/-2 | 220+/-2 |

| CCD Size | 9.0(1/1.8") | 11.0(2/3") | 11.0(2/3") | 11.0(2/3") | 7.2(1/2.5") | 9.0(1/1.8") | 11.0(2/3") | 16.0(1") | 16.0(1") | 16.0(1") | 16.0(1") |

| F/# | 8 | 10 | 10 | 13.6 | 8 | 8 | 10 | 8 | 8 | 8 | 8 |

| N.A. | 0.0188 | 0.015 | 0.015 | 0.011 | 0.0088 | 0.014 | 0.011 | 0.031 | 0.034 | 0.22 | 0.23 |

| MTF | ≥100 | ≥83 | ≥83 | ≥63 | ≥100 | ≥95 | ≥80 | ≥110 | ≥110 | ≥115 | ≥115 |

| DoF(mm) | +/-7@F16 | +/-7@F16 | +/-7@F16 | +/-9.7@F22 | +/-32.5@F16 | +/-13@F16 | +/-13@F16 | +/-2.5@F16 | +/-2.1@F16 | +/-5.3@F16 | +/-4.7@F16 |

| Distortion | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

| Telecentricity | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

| Interface | C-Mount | ||||||||||

| Total Length | 166.2 | 166.3 | 166.2 | 167.7 | 132.8 | 150 | 150 | 205.7 | 215.4 | 214.9 | 214.9 |

Telecentric lenses, designed mainly to correct the aberration of traditional industrial lenses, can remain the magnification rate of the obtained image unchanged within a certain object distance, which is a very important application to the situation where the measured objects are not in the same surface. The telecentric lens has always been favored by the machine vision applications which have high requirements for lens distortion due to its unique design of parallel optical path.

Telecentric lenses have its own distinctive optical characteristics: high resolution, wide depth of the view, extremely low distortion, and its particular design of parallel light.

The telecentric lenses can effectively solve some problems of ordinary lenses, so they can be used in high-precision measurement etc. The telecentric lens is a high-end industrial lens, usually with a relatively outstanding image quality, which is especially suitable for the application of dimensional measurement.

No matter where you are, you will have the same magnification when you refocus at a specific distance. The telecentric lens can provide with superior image quality, and the distortion is smaller than the traditional fixed focal lens. This optical design makes the image surface more symmetrical, which can be used for the precision measurement of the software.

The telecentric lenses are mainly used for precision measurement. In the precision optical measurement system, because the existence of some restricting factors in the ordinary optical lens, such as the error caused by the distortion of the image, the error caused by the improper selection of the perspective, the uncertainty of the boundary caused by improper light interference, and so on and the accuracy of measurement is affected. And telecentric lenses can effectively reduce or eliminate the above problems, therefore, the telecentric lens has become the decisive component of the precision optical measurement system and its application fields are becoming more and more extensive.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr