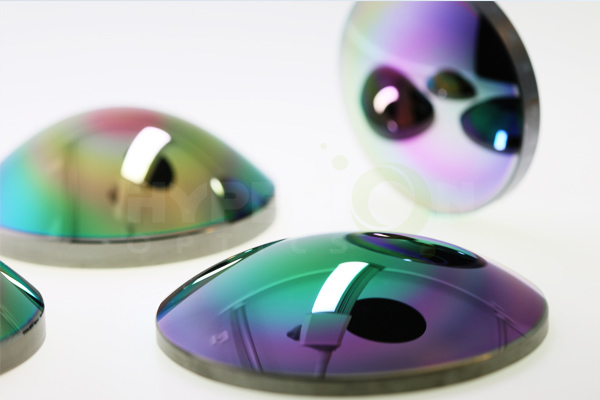

At Hyperion Optics, with decades fabrication experiences, we have been providing our customer a vast number of achromatic lenses for their applications in different precision grades, please check our test plate radius available online for download to save your cost on custom achromatic doublet lens design. Particularly for cost-sensitive design, our series production capability always ensures a satisfying pricing solution.

As optical designers widely use doublets which contribute latitude to eliminate chromatic and spherical aberrations more thoroughly. We also provide excellent suggestions for glass material selection in individual design as we distinguish the importance of refractive index precision in material selection stage despite the design data in software.

Universally, with particular flint glass designers might choose, certain glass’ deliquescence attribute lead to cosmetic failure after polishing, or even affect the transmission after coating. Let us help to avoid such problem in your design to live process.

COMMERCIAL GRADE | FACTORY STANDARD | PRECISION GRADE | |

Diameter Tolerance(mm) | ±0.05 | ±0.03 | ±0.0125 |

Center Thickness(mm) | ±0.01 | ±0.03 | ±0.025 |

Radius (%) | ±1% | ±0.5% | ±0.3% |

Focal Length Tolerance (%) | ±3% | ±1% | ±0.5% |

Cosmetic(MIL-C-13830A) | 100-80 | 40-20 | 10-5 |

Figure Tolerance in λ(Pow/irreg) | 3 - 1 | 2 - 1/4 | 1 - 1/10 |

Centration (Arc min) | 6 | <3 | <1 |

Dia. To Thick Ratio | 9~50:1 | ||

Coating (T% avg) | 96-98% | 99% | 99.5% |

Materials | |||

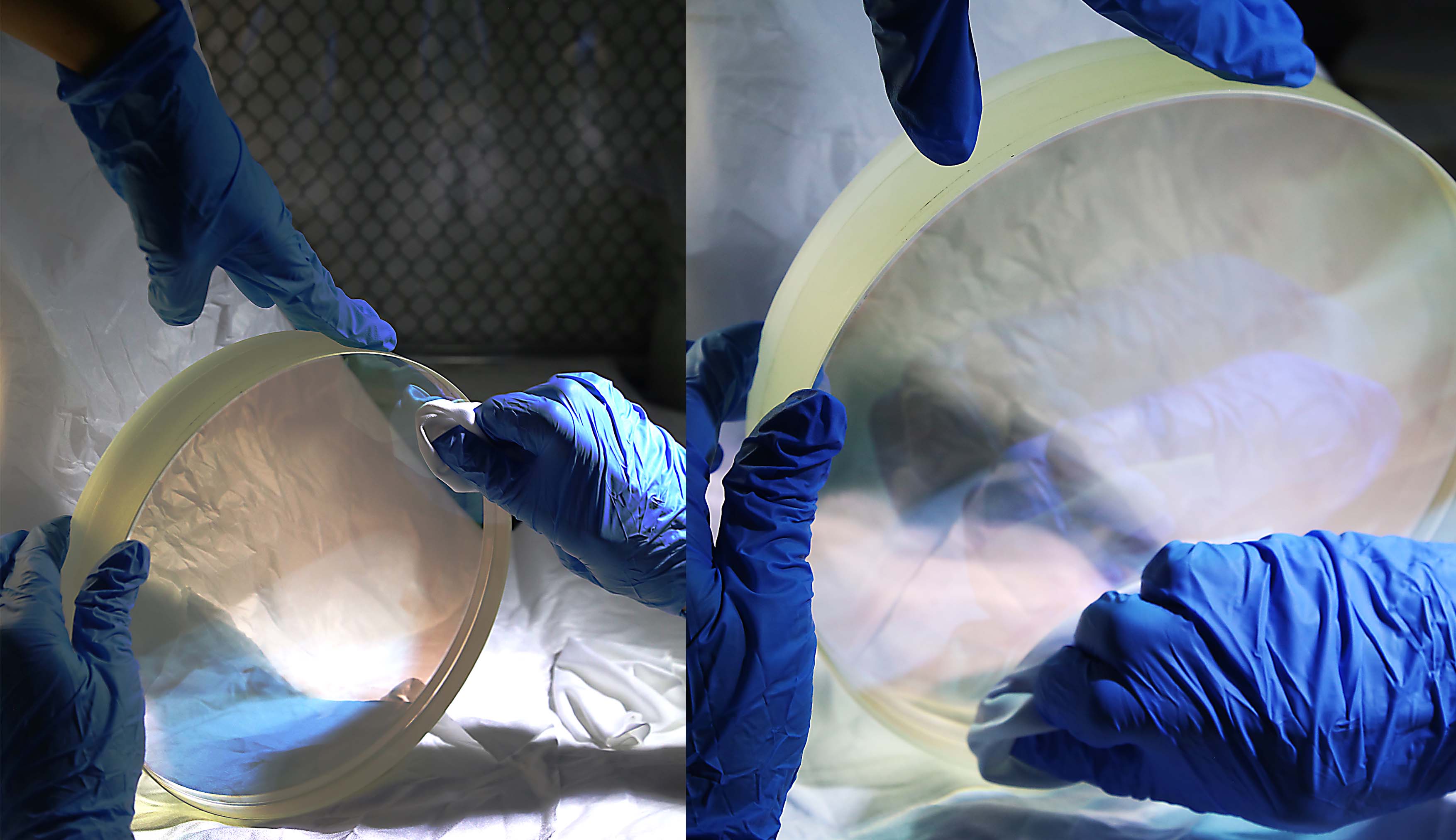

We are also able

to provide custom design in large diameter up to 8 inches achromatic lenses, including cylindrical and achromatic triplet lenses.

For extremely precision sensitive system requirement, please contact us for further information, our engineers are more than happy to evaluate your design and have our experiences of manufacturing input help to define the most appropriate tolerances.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr