Many customers who want to customize optical lenses are not professionals in the optical industry and may not be familiar with the technical requirements when making demands for their customized lenses. So, what do you need to know before customizing optical lenses?

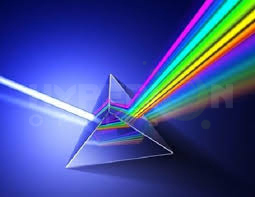

Firstly, you should inform the technical personnel about what your lens will be used for. This will help the technical team analyze and design the lens more accurately. Of course, if the application involves trade secrets, that is a different matter. The spectral range of the optical lens application needs to be known so that the lens design can take into account color aberration, material properties, and other factors. For example, the lens may be designed to work with monochromatic light sources, such as red, green, blue, or white light, or near-infrared, short-wavelength infrared, mid-wavelength infrared, long-wavelength infrared, etc.

The focal length (f), field of view (FOV), and CCD sensor size of the lens are all interrelated. The field of view is calculated using the formula: FOV=2×arctan(CCD size/2f). The concept is easy to understand. The longer the focal length, the larger the target being magnified, and the smaller the field of view.

The aperture value F/number (NA) determines the amount of light that enters the lens and also affects the resolution of the lens. Generally, the larger the aperture, the higher the brightness of the image. In low-light environments, a larger aperture optical system should be used. However, a larger aperture increases the difficulty of lens design, complexity of the opto lens, and cost. We should always strike a balance between the usage requirements and cost.

The numerical aperture and aperture are the same function. The aperture size is usually marked on photographic lenses, while the numerical aperture is used for microscopes and similar lenses. Note that the larger the numerical aperture, the smaller the aperture size. For instance, an F1.4 lens has a large aperture, while an F16 lens has a small aperture.

MTF (modulation transfer function) is a standard that comprehensively evaluates the imaging quality of an opto lens. The MTF two-dimensional coordinate curve usually has the Y-axis as the value (0-1) and the X-axis as the spatial frequency (lp/mm), which is the number of "line pairs." Low frequency evaluates the image contrast, and high frequency evaluates the lens's clarity and resolution, which is the ability to resolve fine details. For example, for photographic lenses, the contrast is usually evaluated at 10lp/mm, and MTF values above 0.7 is considered good. The high frequency is evaluated at 30lp/mm, and it is recommended that the value within half of the field of view is greater than 0.5, while the value at the edge of the field of view is greater than 0.3.

For some optical instruments or industrial lenses, a higher demand is placed on high frequency. How can we calculate the high frequency we want to evaluate? It is actually straightforward: Frequency=1000/(2×sensor pixel size). If your sensor pixel size is 5μm, then the MTF high frequency should be evaluated at 100lp/mm, and an MTF measurement higher than 0.3 indicates a relatively good lens.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr