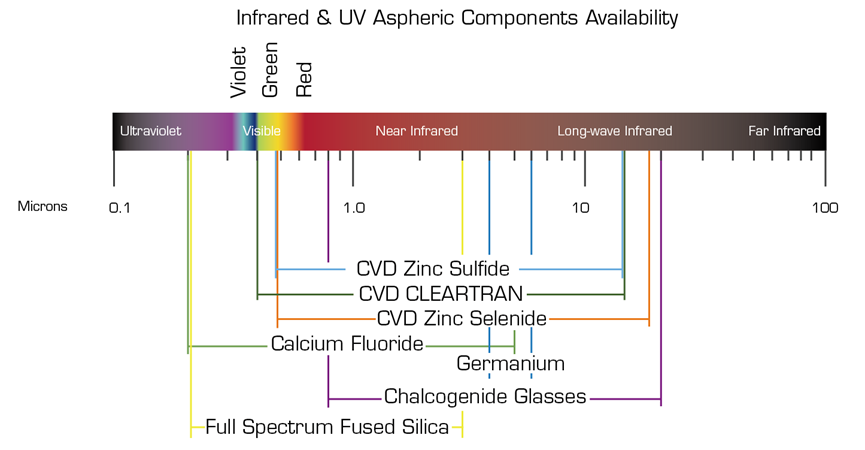

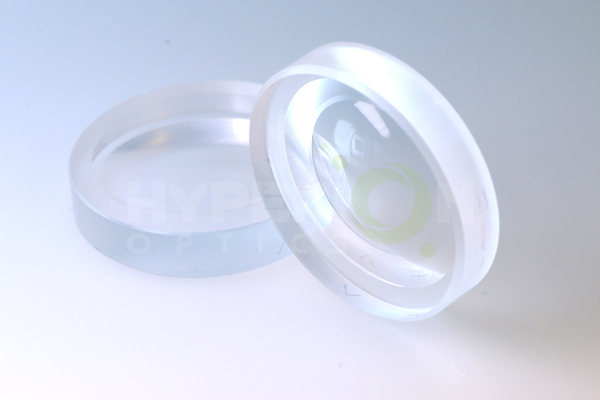

Hyperion Optics works with various infrared materials. In recent years, we have seen a growing demand for IR aspherical components due to their ability to reduce the number of elements within the system while maintaining reliable performance; this makes aspherical parts an excellent choice in Low Rate Initial Production (LRIP) projects. Our IR aspherical lenses manufacturing capability covers from 0.8 microns upwards to 12 microns for IR application, from a combination of materials needed in order to reach the required application needs.

Equipped with an Ametek Single-Point Diamond Turning machine, Hyperion Optics is capable of processing the following infrared and UV materials for IR aspherical lenses:

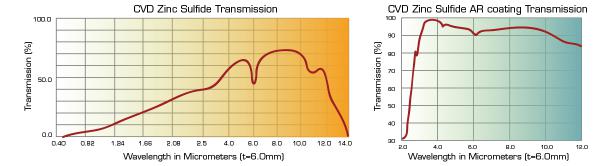

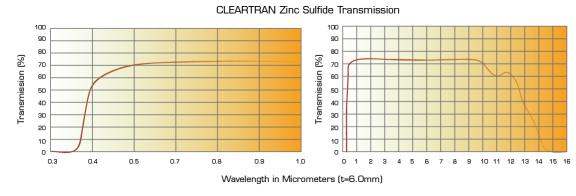

Zinc Sulfide (CVD CLEARTRAN available), Zinc Selenide, Germanium, Chalcogenide glasses (available in both Schott and NHG IRG materials), Calcium fluoride, and Silicon.

Please contact our experienced engineers for performance consultation and print assessment.

MOQ starts at two pieces to ensure optical performance approval. Our fast asphere prototyping has become one of our most popular services for Low Ratio Initial Production (LRIP) projects. We can process both spherical and aspherical parts simultaneously for custom objective and/or eyepiece designs, thereby securing reliable timeline management to meet the tight timing requirement. In addition, we offer competitive pricing for aspheric coating within our prototyping packages.

1. Built to print, Hyperion Optics fabricates IR aspherical lenses and provides inspection report by your print.

2. There is a lack of Chalcogenide materials integration in optical designs for IR applications, which is a big missed opportunity. At Hyperion Optics, the combination of Chalcogenide glasses and regular IR materials can provide a cost-effective solution with superior optical performance.

3. Hyperion Optics runs in-depth mapping and optical performance tests on component-level and/or lens system level products; and provides redesign, optimization, manufacturing, and assembly services.

4. For SWIR prototyping projects, we adopt injection molding processing for Schott and Ohara glasses at prototyping quantities, which can avoid purchasing high-cost raw materials from overseas, and hence dramatically reduces material investment at the prototyping phase.

Still, finding aspheric lens manufacturers? Leave us a message now.

Manufacturing Limits for Aspheric Surfaces For IR Materials Based on Form Error Tolerance | ||

Form Error 0.5 – 2μm Higher Resolution Profilometry (2-D)1 | ||

Attribute | Minimum | Maximum |

Diameter (mm)3 | 3 | 80 |

Local Radius (mm) | -12 (Concave) | ∞ |

Sag (mm) | 0 | 252 |

Departure (mm) | 0.01 | 20 |

Included Angle (°) | 0 | 150 |

Form Error < 0.5μm Interferometry with Stitching (3-D) | ||

Attribute | Minimum | Maximum |

Diameter (mm)3 | 3 | 80 |

Local Radius (mm) | -13 (Concave) | ∞ |

Sag (mm) | 0 | 252,4 |

Departure (mm) | 0.002 | 1 |

Included Angle (°) | 0 | 120+5 |

Talk to one of our optical engineers to understand how Hyperion Optics can work with you for your developing IR application today.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr