In today's fast-paced world, telecommunication devices play a crucial role in keeping us connected. Whether it's a phone call, video conference, or browsing the internet, these devices rely on advanced technologies to transmit and receive information. One such technology that has revolutionized the telecommunication industry is fiber optics. At the heart of this technology lies optical assembly manufacturing, a process that ensures the efficient and reliable performance of these devices. In this blog, we will explore the significance of optical assembly manufacturing in telecommunication devices and how it has contributed to the fiber optic revolution.

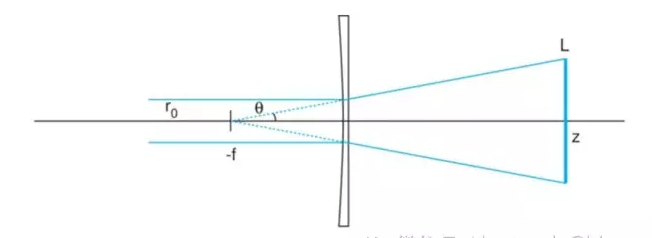

Before delving into the importance of optical assembly manufacturing, let's first understand what it entails. Optical assembly manufacturing refers to the process of assembling various optical components to create functional devices, primarily used in telecommunication. These components include lenses, mirrors, filters, fibers, and connectors. Through precise alignment and integration, optical assembly manufacturing enables the efficient transmission and reception of light signals, ensuring optimal device performance.

Without quality optical assembly manufacturing, the seamless communication we experience today would not be possible. Telecommunication devices, such as fiber optic cables, rely on precise alignment of optical components to transmit data over long distances with minimal signal loss. Optical assembly manufacturing ensures that these components are meticulously calibrated and integrated, resulting in high-speed data transmission, exceptional clarity, and reliability.

As technology continues to advance, so does the field of optical assembly manufacturing. Manufacturers are constantly researching and developing innovative techniques to improve the performance and efficiency of telecommunication devices. One such advancement is the development of automated optical assembly manufacturing systems, which significantly reduce production time and increase accuracy. Additionally, the use of advanced materials and coatings further enhances the durability and performance of these devices.

When it comes to optical assembly manufacturing, Hyperion Optics stands out as a leader in the industry. With decades of experience and a team of dedicated professionals, Hyperion Optics has been at the forefront of developing cutting-edge solutions for the telecommunication industry. Their state-of-the-art facilities, coupled with rigorous quality control measures, ensure that every optical assembly they manufacture meets the most stringent standards.

In conclusion, optical assembly manufacturing plays a pivotal role in the fiber optic revolution within the telecommunication industry. Thanks to this process, telecommunication devices can transmit and receive data with exceptional speed, clarity, and reliability. As technology continues to advance, optical assembly manufacturing will continue to evolve, enabling us to stay connected in an increasingly interconnected world. With Hyperion Optics leading the way in innovation and quality, the future of telecommunication devices looks brighter than ever.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr