In precision optical systems, the slightest deficiency in opto-mechanical design will impair the performance of the most sophisticated optical components. When customizing optics, many clients neglect the impact of opto-mechanical design shortcomings to the overall system. Hyperion’s design and optimization services can help prevent prototyping/ design pitfalls.

First and foremost, our engineering team seeks to fully understand your optical goals and the system performance requirements. Before proposing a mechanical structural design, our team will gain in-depth insights about your application needs through a series of technical communication. This investment in the preliminary design phase is critical for the efforts in setting the appropriate opto-mechanical design constraints based on the system function. These constraints enable us to convert the precision optical components into a high-performance and reliable optical system.

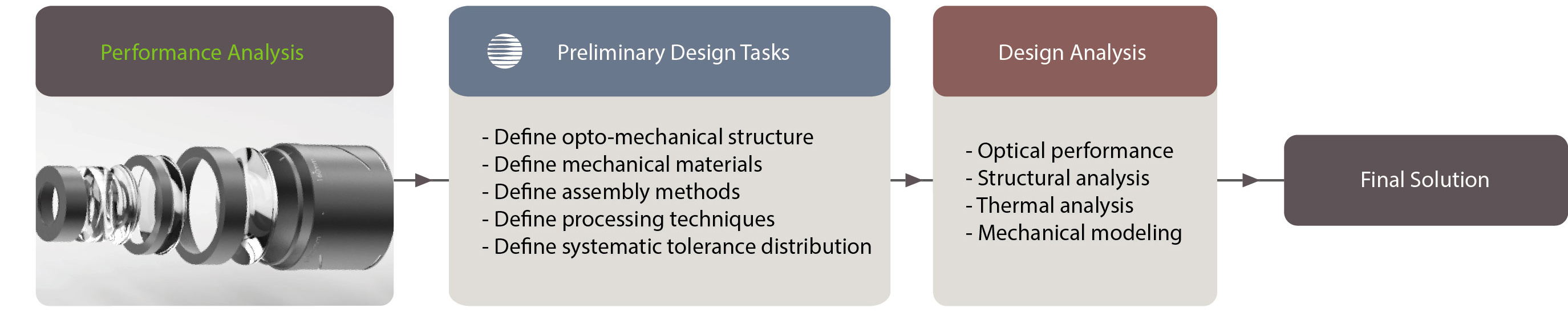

Hyperion's vigorous work process is designed to result in an optimal solution:

1. Our mechanical team works with you to understand the requirements of the optical parameters in respect to the mechanical system

2. Our optical team works with you to understand the impact of mechanical design on the overall optical system performance

3. Our mechanical and optical engineering teams work collaboratively to:

a. Formulate spacing and centration requirements of complete optical components

b. Determine material specifications

c. Determine packaging requirements (e.g. minimum and maximum size and weight restrictions, environmental standards such as shock, vibration, operating temperature)

d. Perform cost and production yield analysis

e. Finalize production schedule and requirements

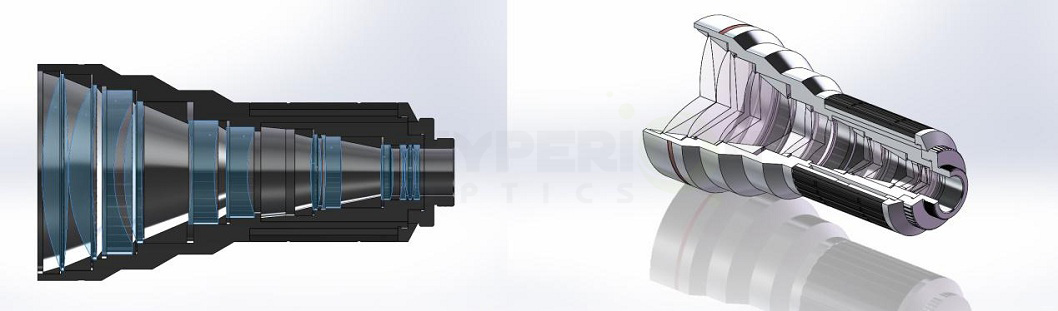

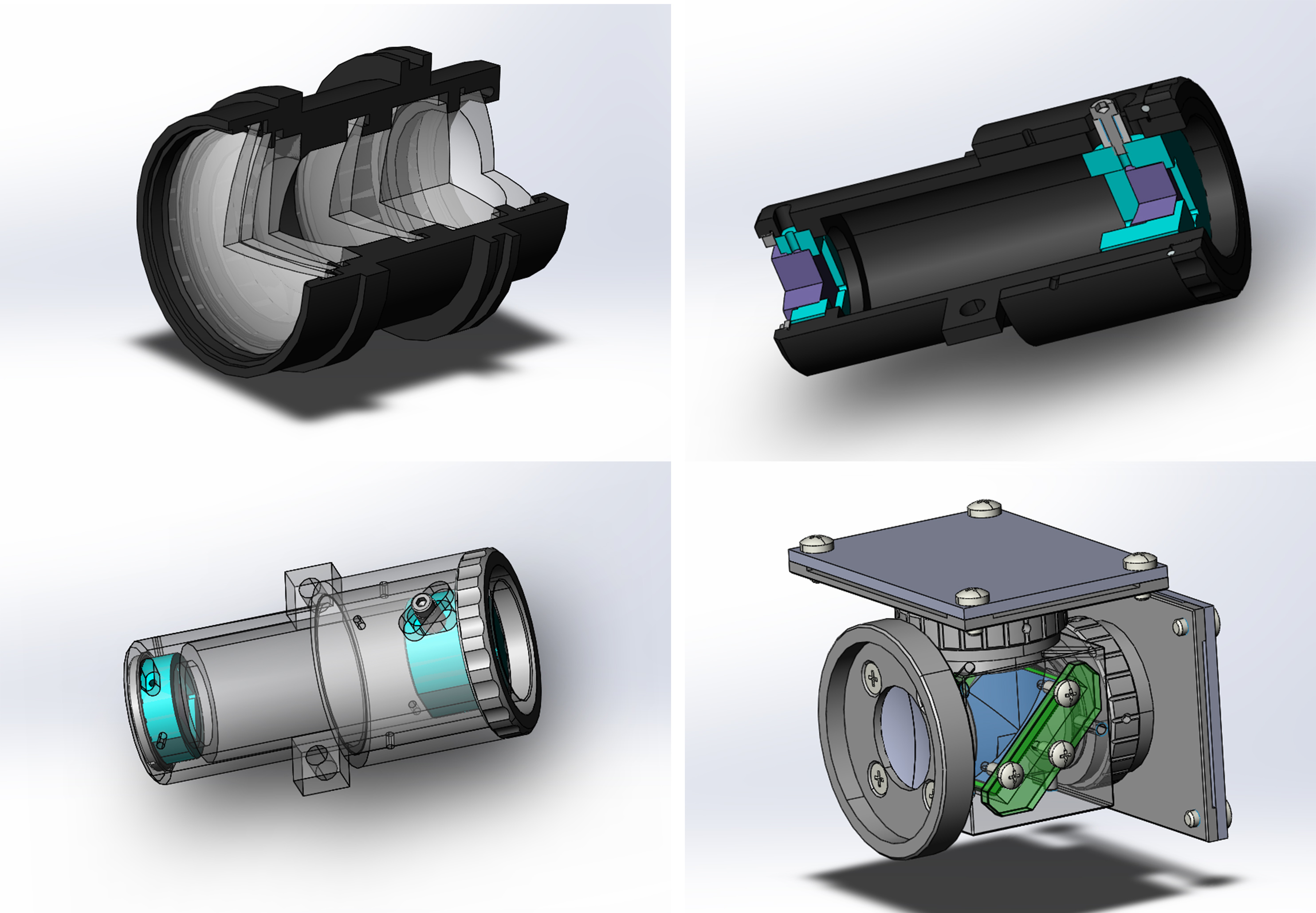

4. Verify the design by using SolidWorks to create 3D models and structures

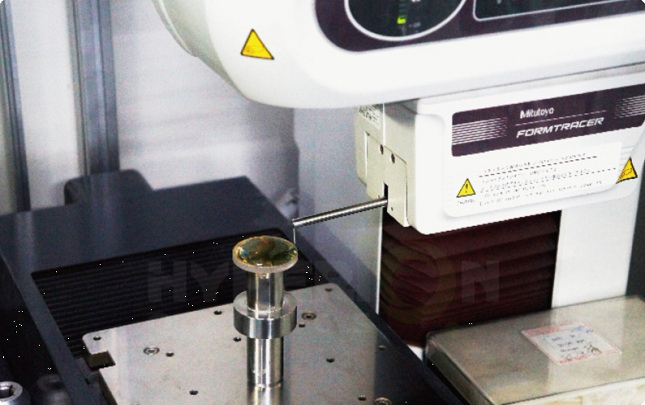

Hyperion also offers

proof-of-concept services for individual optical element leveraging systematic

engineering methods to ensure that your solution will meet your design

expectations. Specifically:

Prototyping Services for Opto-mechanical Components:

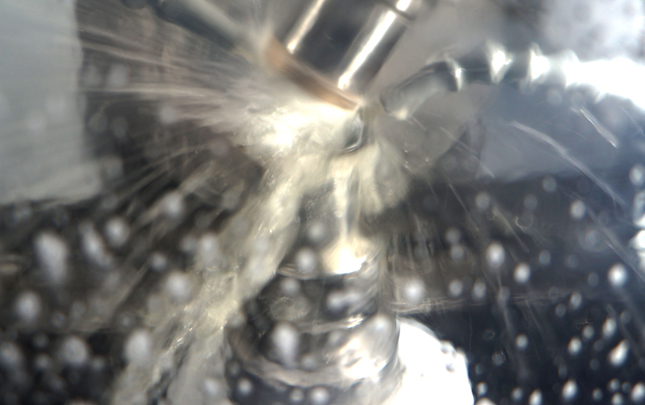

Hyperion offers prototyping for various component materials, including optical glass, plastic, and metal (such as Alunimum, stainless steel, copper, brass).

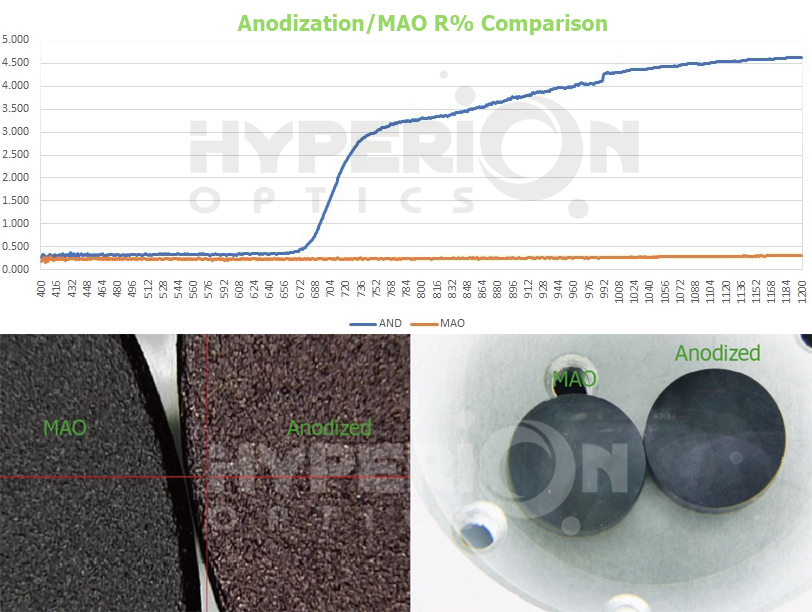

At the same time, we will

also recommend the most suitable metal oxidation process based on your working wavelength.

For instance, for NIR or SWIR applications, we propose Micro-arc Oxidation (MAO)

blackening instead of conventional anodization blackening (AND). MAO blackening

offers the unique advantages where Ravg can be reduced to a minimal level. The

below MAO (arc oxidation) and traditional anodization blackening (AND)

reflectivity comparison showcases this advantage:

Starting from the

near-infrared band, arc oxidation can maintain the low reflectivity of the

inner wall of the device, thereby reducing the noise of the entire system and

improving the optical performance.Our team conducts various

research and R&D on metal surface oxidation to help our customers arrive at

the best treatment decision with regards to opto-mechanical components.

Our experience is transferable over a wide variety of commercial applications; we have been continuously helping our customer to build:

| Collimators including LED | Image Processing | ||||

| Microscope Objectives | Video Games and Optical Gadgets | ||||

| Zoom Lenses | Night Vision | ||||

| Metrology Systems | IR Systems | ||||

| Laser Marking Systems | Robotics | ||||

| Ophthalmoscopes | Motion Capture | ||||

| Endoscopes | Distance Measurement | ||||

| Servo Systems | Barcode Readers | ||||

| Confocal Imaging | 3D Displays |

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr