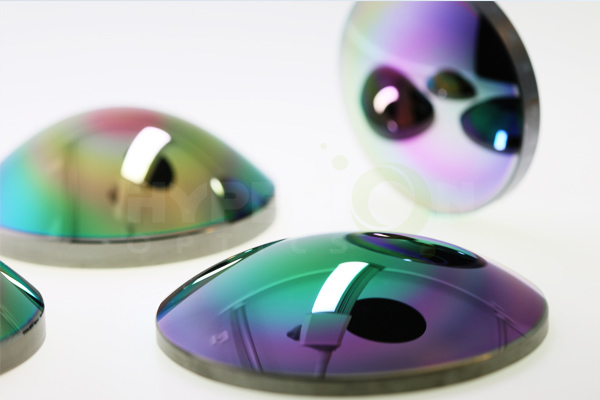

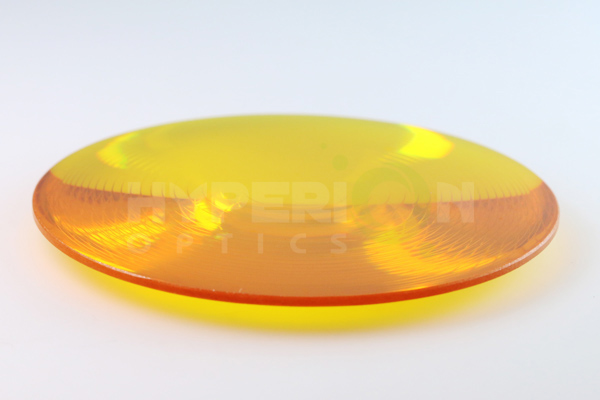

Hyperion Optics’ manufacturing equipment expand our aspherical products’ capabilities to LWIR applications, from high precision VIS imaging systems to infrared athermal lenses. Our process enables precise fabrication on optical glasses and infrared materials including Germanium, Zinc Sulfide, Zinc Selenide, Calcium Fluoride, Chacolgenide glasses, and more.

We simulate every aspherical equation and all specs we received from our client to make sure that we are capable of delivering products that meet the requirements and provide suggestions based on our study and understandings. Thus we are absolutely trust-worthy aspheric lens manufacturer for you to choose. We would run a trial test on H-K9 glass to verify the design feasibility for complicated designs and provide the profiler map for your reference.

Hyperion’s competitive pricing on high-quality aspherical parts manufacturing helps clients to leverage aspherical surfaces in their design to achieve better system performance and/or compactable goal, meanwhile leading with pricing advantages in the market.

Work with Hyperion on LRIP (Low Ratio Initial Production) projects, such as 5-10 pieces for an optical feasibility study, to 200-piece to 500-piece volume production. Optional blanket order with a multiple delivery schedule is available to fit your production planning. Contact Hyperion today to chat about your specific needs.

The spherical lens is with a constant curvature from the center of the lens to the edge, while the aspherical lens changes continuously from the center to the edge. In photographic lenses, many aberrations must be corrected in order to ensure optical performance. If only the spherical lens is used to correct, it is necessary to have a lot of lens combinations for the technical requirements For special advanced lenses, spherical lenses are sometimes unable to correct aberrations to the extent of user satisfaction. The aspheric lens has a better radius of curvature and can maintain good aberration correction to obtain the desired performance. The application of aspheric lens brings excellent sharpness and higher resolution, and the miniaturization design of lens becomes possible.

a.Spherical aberration calibration

Aspheric lenses are used to replace spherical lenses, and the most obvious advantage is that the spherical aberration of spherical lenses in collimation and focusing systems can be corrected. By adjusting the surface constant and the aspheric coefficient, aspheric lens can eliminate spherical aberration to the maximum extent. Aspheric lenses (rays converge to the same point and deliver optical quality) basically eliminate spherical aberration generated by spherical lenses (rays converge to different points, leading to blurred image).

In order to increase the effective focal length to eliminate spherical aberration, three spherical lenses are needed. However, with only one aspheric lens (high numerical aperture, short focal length) can achieve the same goal and it can also simplify the system design and improve the transmittance of light.

b. System advantages

The aspheric lens simplifies the elements involved to improve the optical quality and improves the stability of the system. It can achieve similar or better optical quality, thus reducing the system size, increasing cost ratio and reducing the overall cost of the system.

c. Additional performance benefits

Although there are a lot of different techniques out there to correct aberrations created by the spherical lens, however, these other technologies are far less capable than aspheric lenses in terms of imaging performance and flexibility.

When using an aspheric lens, its additional aberration correction supports the user to maintain a good image quality while implementing the system design of high luminous flux.

Various types of aspheric lenses have their own comparative advantages. Major considerations inclouding: volume, quality, and cost.

a. The precision glass forming aspheric lens has the characteristics of mass production and high thermal stability. It is suitable for occasions with high volume, high quality and high thermal stability requirement.

b. The aspherical lens of precision polishing has the characteristics of short molding cycle and no need of mold, it is suitable for the occasion of sample making and small batch sample.

c. Mixed forming aspheric lens, which has the characteristics of spherical aberration and chromatic aberration, it is suitable for the occasion of wide spectrum, large quantity and high quality.

d. The plastic forming aspheric lens has the characteristics of low cost and light weight, which is suitable for occasions of large quantity, moderate quality and low thermal stability requirement.

The aspheric lens, with the curvature radius changing with the center axis, is used to improve optical quality, reduce optical elements, and reduce design costs. The aspheric lens has a unique advantage over spherical lens, therefore, it has been widely used in optical instruments, images and optoelectronic industries, such as digital cameras, CD players and high-end microdevices.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr