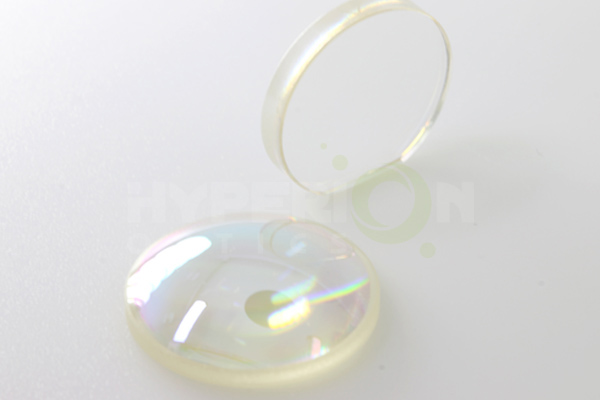

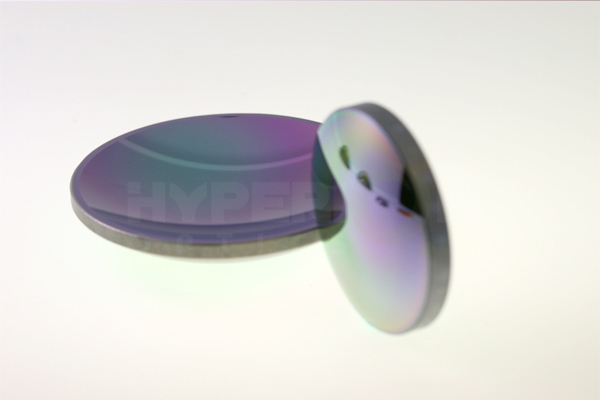

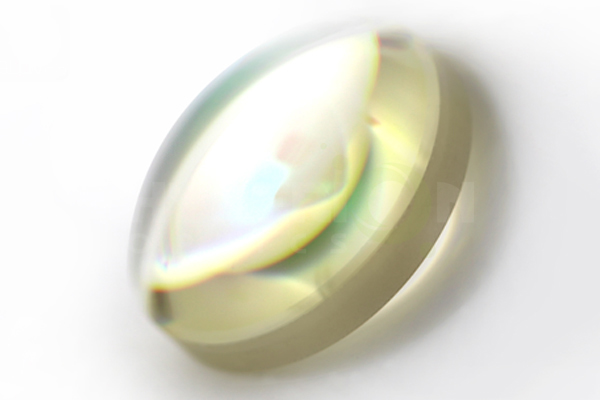

We work on a wide range of infrared materials that covers almost full infrared spectrum. Hyperion Optics supplies Zinc Selenide, Zinc Sulfide, Silicon, Germanium, Gallium Arsenide, and Calcium Fluoride, Barium Fluoride as well as Chalcogenide spherical lenses and aspherical lenses. We use laser based edging device to control MWIR and LWIR lenses’ decenter deviation, and test on reflective centering station to fulfill extreme precise tasks.

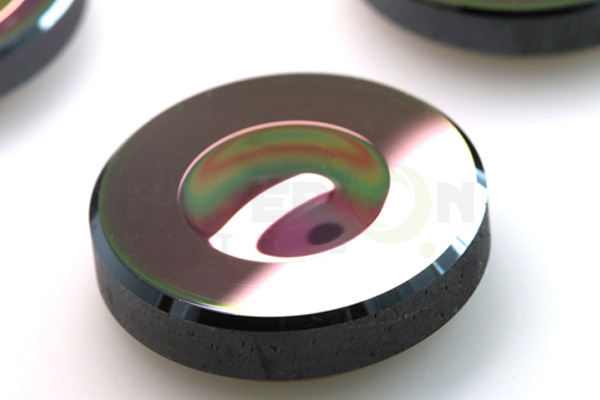

Zinc Selenide has great transmittance through the band 0.5-22μm, especially at 10.6μm, and is commonly used in thermal imaging and FLIR systems, also its outstanding low absorption coefficient and high resistance to thermal shock makes it an ideal choice for high power CO2 laser applications. For laser ZnSe components please browse our Laser Optics category for more information.

Since Zinc Selenide is a relatively soft material that scratches and digs can be easily remained on the surfaces during processing flow, it is not recommended for use within harsh environments, Hyperion Optics' advanced manufacturing techniques for ZnSe ensure superior surface quality compared to our competitors. For cosmetic sensitive systems, our best effort can reach 20-10 in S/D grade. ZnSe aspheric lenses are also available for your application; please refer to IR Aspheric Lenses for more information. ZnSe Dome optics are also available in our Dome category.

Our infrared lenses are also available with AR coating according to specific requirement. Please take great care when handling, mounting and cleaning infrared lenses, further, For your safety, please follow all proper precautions, including wearing gloves when handling these lenses and thoroughly washing your hands afterward.

In addition, along with our outstanding aspherical (including DOE surface) manufacturing capability, Hyperion Optics is definitely one of your best choices in SWIR/MWIR/LWIR lenses development project.

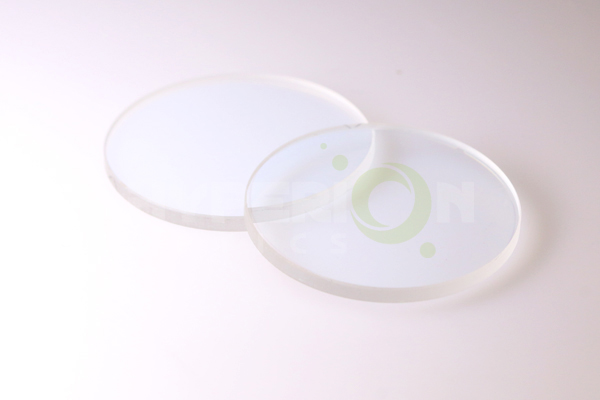

Infrared optical system is just using limited materials for medium wave infrared and long wave infrared. The basic of infrared technology is infrared detector and infrared optical materials. The development of infrared technology also promotes the development of infrared optical materials. The development of infrared materials are always strongly linked with infrared technology and photoelectronic technique. When studying and using infrared optical materials, we must refer to their optical and mechanical properties, such as transmittance, absorptivity, emissivity, index of refraction, dispersion and breaking strength, breaking tenacity and the influence of environmental conditions to the material properties, such as resistance to heat shocks, sand erosion, rain erosion. Since infrared materials always have high refractive index and high reflectivity, that requires an anti-reflective coating, or the transmittance of system will be very low.

1. Infrared optical materials are not only limited in types but also very expensive.

2.The temperature coefficient of refractive index of some materials is large, so the focal length will differ a lot according to the temperature. If the working temperature range is wide, infrared optical materials are needes or take some efficient measures to compensate.

3.Some optical materials are fragile with bad chemical stability, that causes the difficulties in processing and installing and low production yield.

4. Many optical materials are opacity, they will there will show different colors because of different materials and band.

5.Infrared optical materials will have radiation when heated, which can cause stray light.

For infrared optical materials, we should firstly pay attention to their optical properties, then determine the optical band that suits the materials, thirdly, considering its mechanics and thermal properties. In the situation of same band, while choosing from various materials, optical property is the most important and basic property of infrared optical materials. The optical property of infrared optical materials is an abroad statement, in fact it includes many things, for example, the relation between reflection of light, absorptivity and temperature, the relation between transmittance and temperature, emissivity and microwave dielectric properties of infrared optical materials. Infrared optical materials are widely used in many kinds of infrared windows, camera lens and lens for Co2 laser.

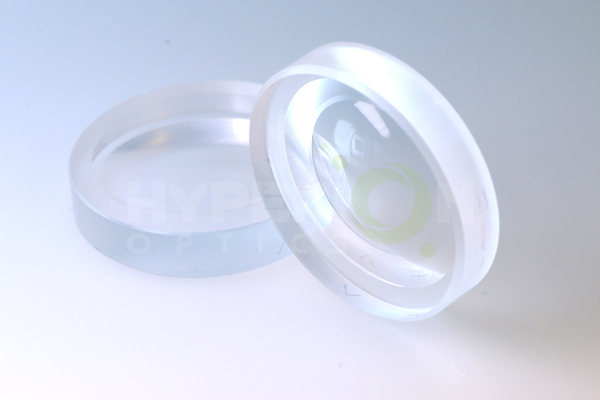

Germanium is the most common optical material, it can not only be used in long wave infrared but also medium wave infrared. Germanium should be careful treated in the process of light processing, coating and adjustment. Because the usage of germanium is wide, its problems can all be solved compared with its advantages.

Silicon is a kind of crystal material similar to germanium. The refractive index of silicon is lower than germanium, it has enough advantage in controlling aberration. Besides, the dispersion of silicon is quite low. Silicon can be processed by diamond turning, but it is difficult and it is also harmful to turning tool. The common way to process is polishing.

Compared to oxide glass, chalcogenide glass has larger density and weaker bond strength. At present, the chalcogenide glass that used in infrared optical device always contains arsenic. However, with the improvement of environmental awareness and product standard all over the world, environmentally-friendly non-arsenic glass will become a trend.

Zinc selenide and zinc sulfide also belong to infrared optical materials, zinc selenide is more expensive than zinc sulfide, it is suitable for optical system that has less requirement for absorptivity.

Calcium oxide can be used for optical components like prism, lens and large-diameter lens and windows. It can eliminate secondary spectrum and it is useful for spectral apochromation.

Infrared lens are widely used in night vision goggles, imaging system and medical apparatus and instruments. Hyperion Optics is good at producing infrared lens of various materials, like germanium, silicon, zinc selenide, calcium fluoride, magnesium fluoride, zinc sulfide, sapphire and so on.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr