Optical Mirrors are designed to reflect light for a variety of applications, including beam steering, interferometry, imaging, or illumination. Optical Mirrors are used in a wide range of industries, such as life sciences, astronomy, metrology, semiconductor, or solar.

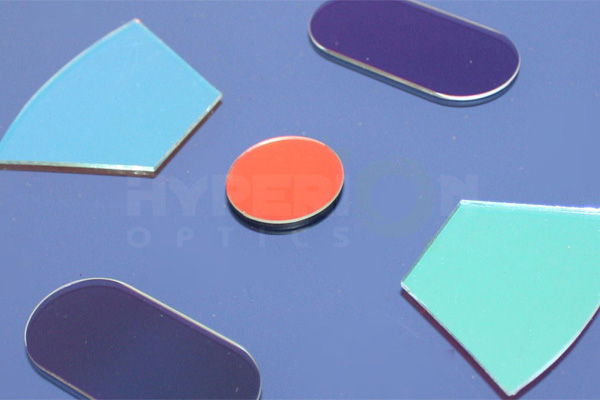

Hyperion Optics offers a range of laser, flat, metal substrate, focusing, or specialty Optical Mirrors in a multitude of reflective coating options, including Protected Aluminum, Enhanced Aluminum, Protected Silver, Protected Gold, or Dielectric. Choosing the proper reflective coating option ensures high reflectivity of the needed wavelength or wavelength range. Optical Mirrors designed for laser applications are optimized for the given laser wavelength. Additionally, Optical Mirrors designed for lasers feature damage thresholds that are suitable for the designated laser. Metal substrate Optical Mirrors are ideal for applications requiring a constant coefficient of thermal expansion between the Optical Mirror and the mount. Optical Mirrors with a concave surface are ideal for light focusing applications.

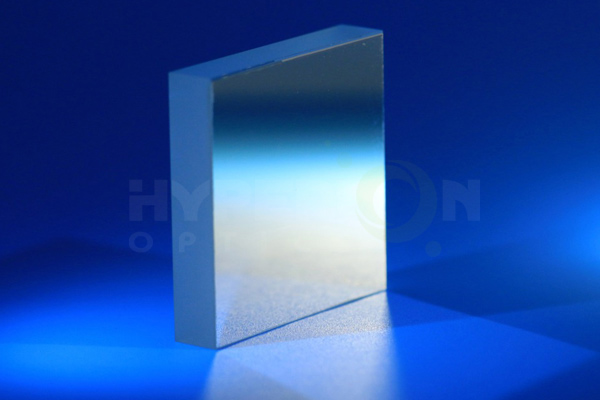

Optical mirrors have a smooth, highly-polished, plane or curved surface for reflecting light. Usually, the reflecting surface is a thin coating of silver, or aluminum on glass. Product specifications for optical mirrors include diameter, radius of curvature, thickness focal length, and surface quality. The diameter or height of an optical mirror is measured straight on. If the optical mirror’s curvature was extrapolated into a sphere, then the radius of that sphere is the radius of curvature for the mirror. There are two thickness measurements for optical mirrors: center thickness and edge thickness. Units of measure include inches, feet, and yards; nanometers, centimeters, and millimeters, and miles and kilometers. With optical mirrors, focal length is the distance from the mirror at which light converges. Surface quality describes digs and scratches. A dig is a defect on a polished optical surface that is nearly equal in terms of length and width. A scratch is a defect whose length is many times its width.

Optical mirrors are made from many different materials, each of which influences the mirror’s reflectivity characteristics. Choices for materials include borosilicate glass, copper, fused silica, nickel, and optic crown glass. Borosilicate glass is also known as BK7 and boro-crown glass. Copper is used in high-power applications because of its high thermal conductivity. Fused silica has a very low coefficient of thermal expansion and is suitable for use with moderately-powered lasers or changing environmental conditions. Ultraviolet (UV) grade optical mirrors are also commonly available. Nickel is used in applications which require resistance to both thermal and physical damage. Proprietary materials for optical mirrors include Pyrex (Corning Inc.) and Zerodur (Schott Glaswerke).

Optical mirrors are sometimes coated to enhance their reflectivity. Choices include bare, enhanced, and protected aluminum; silver, bare gold and protected gold; and coatings made from rhodium and dielectric materials. Enhanced aluminum coatings are used to improve reflectance in the visible and ultraviolet regions. Protected aluminum coatings provide abrasion resistance while protecting the surface of the aluminum, an excellent reflector in the upper UV, visible and near-infrared (IR) regions. Optical mirrors with bare gold and protected gold coatings are used in the near-IR to far-IR regions. Silver coatings provide better reflectance than aluminum; however, silver’s tendency to oxidize and tarnish requires thorough sealing from the atmosphere. Rhodium coatings have a reflectivity of approximately 80% of the visible spectrum.

Mirror is an optical element that uses the law of reflection. In the past, when the mirror was made, it was often silver coated on the glass. The standard process is: after vacuum steaming aluminum on a highly polished substrate, it is then coated with a silicon oxide or magnesium fluoride. Since the law of reflection is independent with the frequency of light, such components have a wide range of working bands and can reach the ultraviolet and infrared regions of visible spectrum, so its application is more and more extensive.

Whether the mirror’s reflective effect is good depends on the wavelength of the incident light (i.e. the light source) and the surface finish of the coating. The output power of the laser can be multiplied if applied with reflector of high reflection ratio. It is reflected from the first reflector, and the reflection image is not distorted without double shadow. If we use a normal mirror, it not only has low reflectivity, but also has no selectivity of wavelength, and can produce double shadow. However, with the coating membrane mirror, the image obtained is not only high in brightness, but also precise and accurate, with clearer picture quality and more realistic color.

The mirror is divided into three kinds in shape: plane mirror, spherical mirror and aspheric mirror. It can also be divided into complete reflectors and semi-permeable mirror by the degree of reflection. The optical mirror is designed to reflect light in a variety of applications, including beam deviation, interferometry, imaging or lighting.

Plane mirror is usually made of silver-plated or aluminium-plated flat glass. A plane mirror is a virtual image of a virtual object. It is the only optical element that does not damage the single heart of the beam and can form a perfect image.

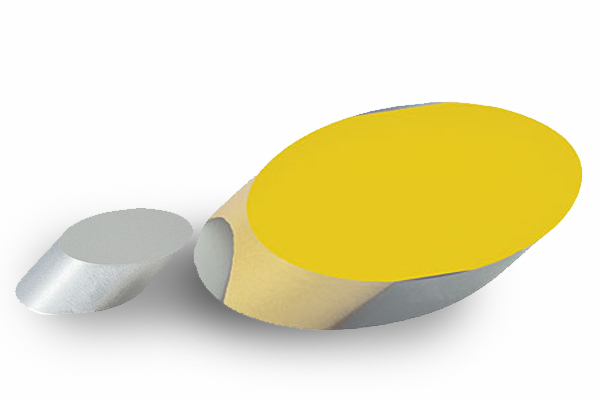

The reflection surface of a spherical mirror is a sphere. If the center of the ball is located on the illuminated face, it is called a concave mirror. If the center of the ball is located on the other side of the illuminated face, it is called a convex mirror. The concave mirror is a convergent mirror. The parallel beam is reflected and will converge at one point, which is the real focus. The light source is placed in the focus position and the beam is reflected back into a parallel beam. The convex mirror is a divergent mirror, and the parallel beam is reflected by it to be a divergent beam, and the backward extension of the reflected ray is delivered to a point, which is the virtual focus. The observation mirror on both sides of the car's cab is a convex mirror, and objects in the distance form a shrinking image near the virtual focus.

Aspheric mirror can be classified into parabolic mirror, hyperboloids mirror, elliptic mirror, tapered surfaces and cylindrical mirror. The beam of a parallel axis of light is reflected in a paraboloid mirror and is concentrated in the focal point of the paraboloid. And in the reflector telescope, it can be used to make the distant star imaging in the focal point. Instead, a beam of light emitted by the focus is reflected by a parabolic mirror and then forms a parallel beam for the searchlight. Hyperboloid and elliptic mirrors are often used in special optical systems to simplify the structure and improve image quality.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr