Hyperion Optics is expertized in challenging custom design and manufacturing microscope objective lenses range from UV to Infrared wavelength, for applications including quantum computing (Observation lenses), please refer to our quantum photonics optics for your further information. Our diffractive limit microscope objective lenses fit for most research oriented labs applications and commercial microscope devices.

We also offer over 60+ various magnifications and numerical aperture specification off-the-shelf lenses for you to pick up from; please download our microscope objective lens catalog. Hyperion Optics works closely with the most advanced quantum computing science companies who are focusing on new banking technology, further gained valuable experience not only in objective lenses but also the integration knowledge of the entire observation unit. Do not hesitate to contact us for free technique support and consultation if you are building your own quantum structure unit, we are more than happy to discuss the feasibility with our own experience.

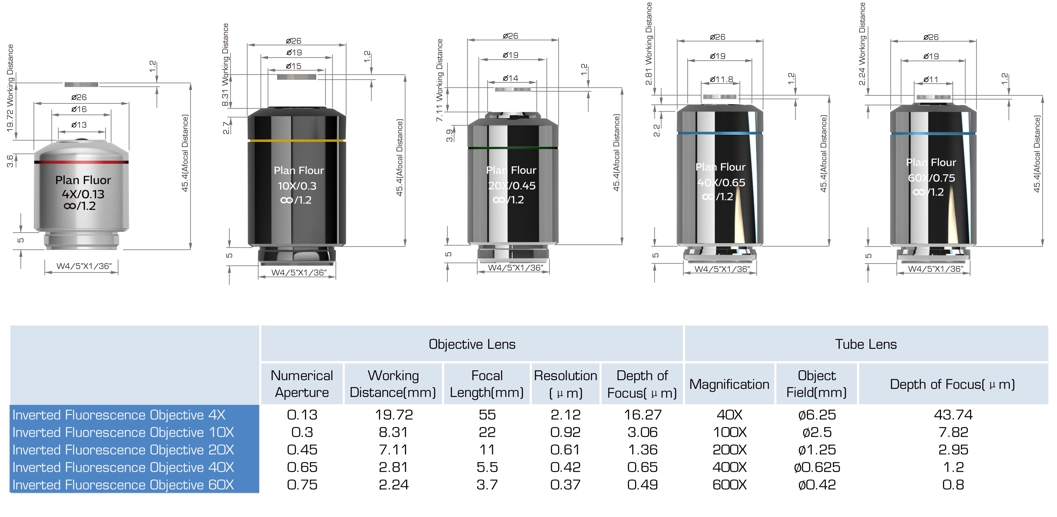

Inverted Fluorescence Objective Lens:

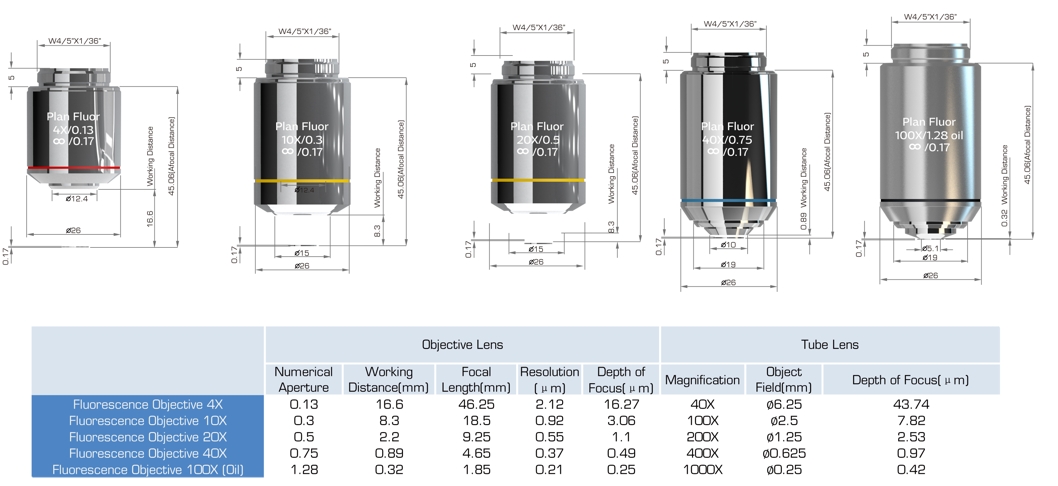

Fluorescence Objective Lens

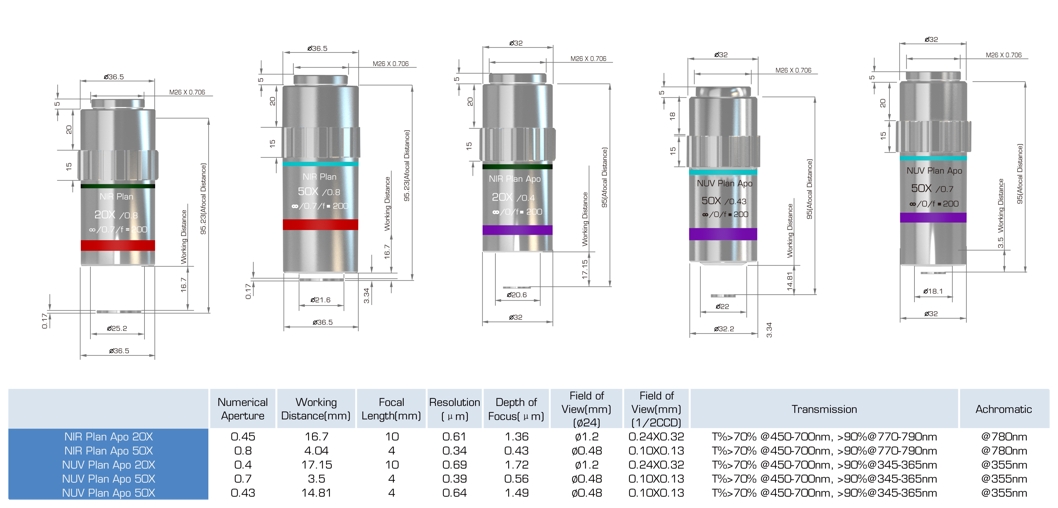

NIR and NUV Plan Apo Objective Lens

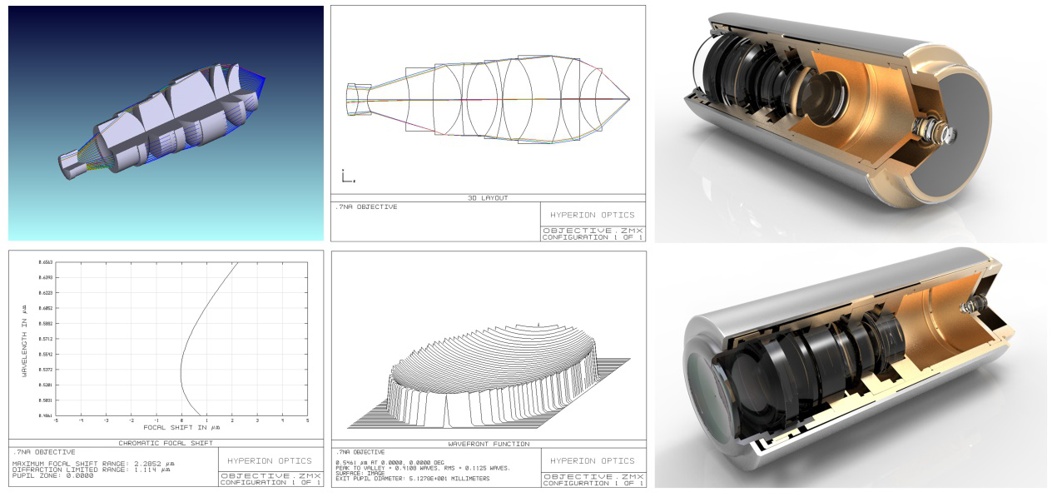

Our capability of DFM( design for manufacturing) input ensures your expectation can be fully met, we have developed unique bordure process which effectively increase optical axis alignment precision to 0.1arcmin ~0.3arcmin per element which is considered critical in microscope objective lenses manufacturing, also with -0.005~-0.015 mm outer diameter tolerance control which almost eliminate assembly error. Our techniques contribute to the performance tremendously, even for diffractive limit applications.

Hyperion Optics has mature and high performance design for achromat, semi-apochromat, apochromat objective lenses. Our manufacturing capability enables us to involve CaF2 (calcium fluorite) sphere or even CaF2 aspherical surfaces in your demanding application, including doublet or triplet with calcium fluorite element adhered. Please refer to our calcium fluorite and aspherical parts manufacturing capability introduction for details.

We are specialized in designing and manufacturing ultra-long working distance, high numerical aperture diffractive limit microscope objectives. We also offer reverse engineering service for your own project development; please refer to our reverse engineering page for more information.

Please download our off-the-shelf microscope objective lenses data sheet or contact us for your own lens development plan.

A microscope lens is composed of a lens or a combination of lenses. It is mainly used to magnify tiny objects to be seen by the human eye.

The function of microscope lens: magnify objects at large magnification.

The normal optical microscope is based on the imaging principle of the convex lens, which is to pass through two images of the convex lens.

At first, it goes through an objective lens (convex lens 1) to form the image, it should be an enlarged inverted image. Take the first image as an object, then the second image through the eyepiece is a virtual image, and it is an enlarged image of a positive image.

Clean the surface of each optical part of the microscope with a clean brush or wipe with mirror paper.

Methods of wiping: wipe off the surface of the lens with a clean brush or a hairdryer, then use a clean flannelette to start from the center of the lens toward the edge running the spiral one-way movement. Wipe it once, then rub it in another place until it is clean. If there are oil stain, dirt, or fingerprints on the lens which can't be wiped, you can use the willow branches wrap with the cotton wool and a mixture of alcohol and ethyl ether (alcohol 80%, ether 20%).

Once the lenses are moldy, it is difficult to remove them. The inner lens of the microscope is more harmful to the inconvenience of wiping. If the mechanical parts are damp, they will rust easily. In order to prevent moisture, we should place 1~2 bag of silica gel as drying agent when we store microscope, besides choosing a dry room.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr